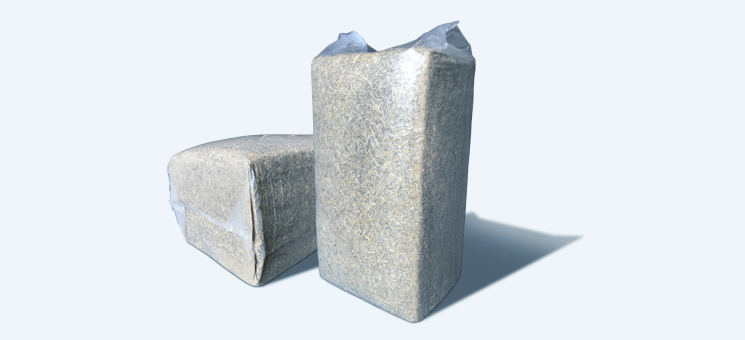

Benefits

- Puncture resistant material reduces waste and the need for repacking

- Optimal size and shape for efficient production

- High strength film for cost effective processing

- High sealability films reduce burst edges and save cost

- Adjustable slip levels for processing efficiency and transit stability

- Compatible with all baling machinery