Benefits

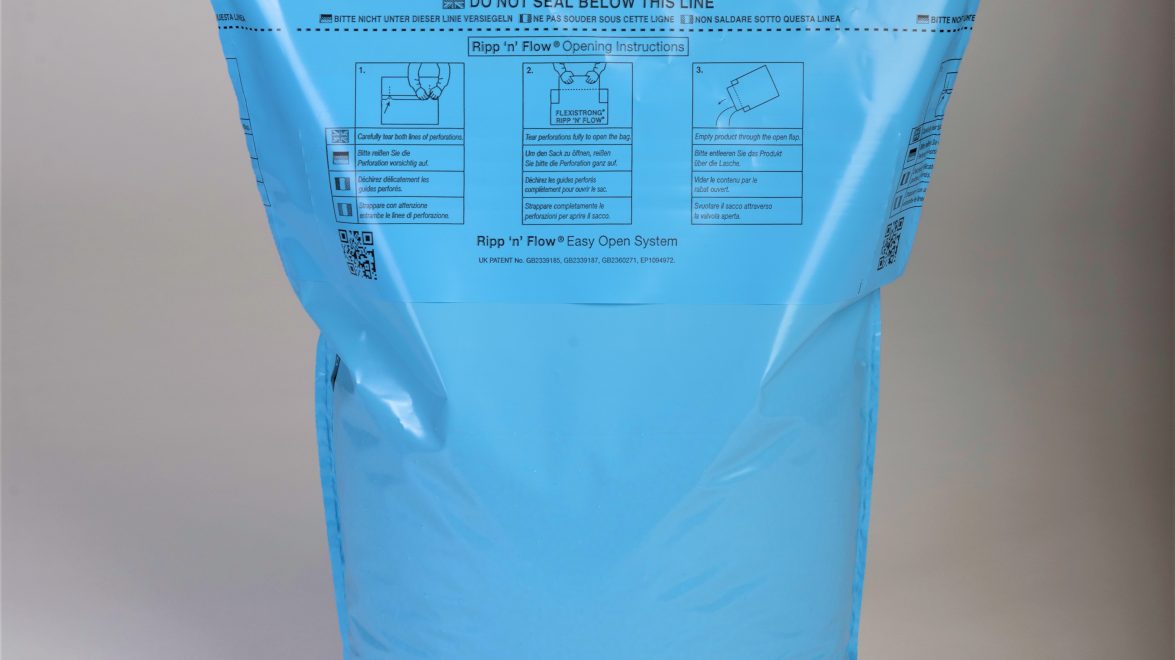

- Eliminates the need for knives

- Easy-open design for speed and ease when decanting and processing

- Reduces the risk of contamination

- Available with our block-bottom to create a stand-up pack

- Comes with tamper evident design

- Bespoke and tailored to your needs

- Suitable for fully or semi-automatic filling lines

- 100% recyclable