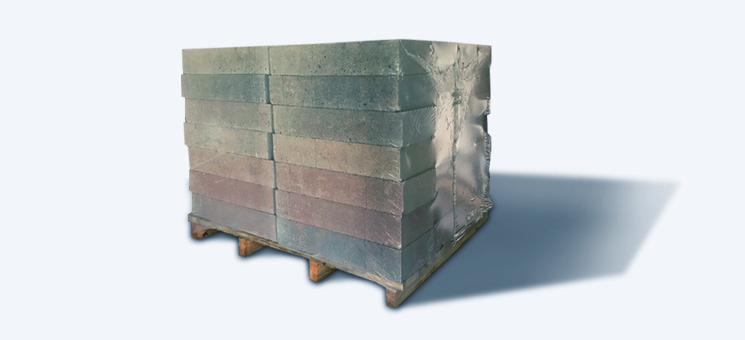

Palletisation options: Protect your products from pallet contamination

Cardboard pallet cards are widely used to provide a barrier between the wooden pallet, and the products stacked onto it. However, there is still a contamination risk with the cardboard, and in addition, the card is not secure and can shift. Flexipol hygiene pallet covers replace cardboard pallet cards and reduce the risk of contamination.Their …