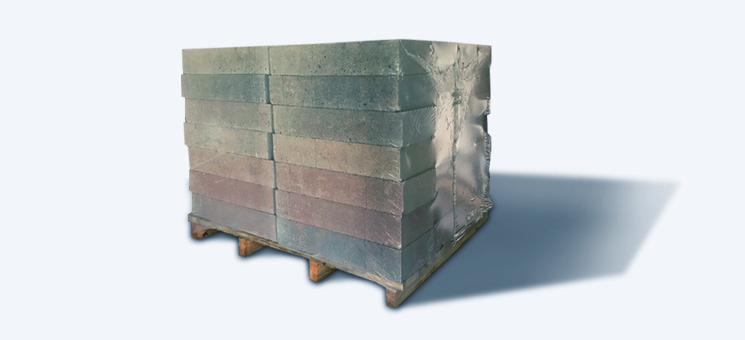

Protect your pallets in transit with specialised shrink film

Weather damage is a problem faced by companies everywhere. With British weather being unpredictable, you need to make sure your pallets are weatherproof. Shrink wrapping them creates a tight, secure fit around your pallet, covering it from top to bottom and protecting it against contamination. Our new Palagan shrink pallet covers secure your finished goods …